Technical Features

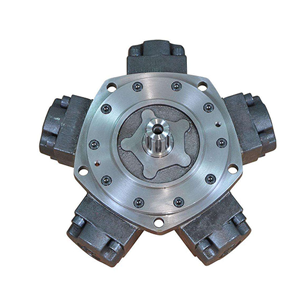

Servo double oil hydraulic drive system with accurate control, energy saving more than 25-45%.

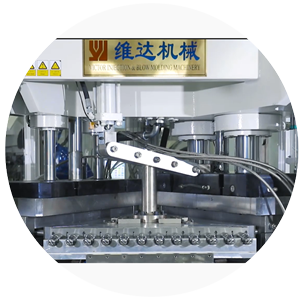

The triangular beam structure has high rigidity and good stability.

Linear guide for barrel movement, low resistance, high precision.

Stripping plate overturn pneumatically, safe and clean.

Optional

Electric preplasticizing, synchronous plasticizing can be realized.

Linear guide for barrel movement, low resistance, high precision.

Electric stripping, energy saving and clean.

Electric table rotation, high precision of rotation positioning.

Product Application

Advantage

Special designed single crossbar dual-cylinder balance clamping system,for fast opening and closing mold while ensuring uniform distribution.

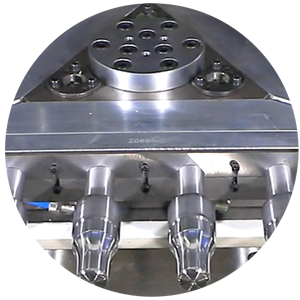

Unique rotating mechanism design, and equipped with automatic lubrication system,ensure rotation precision be consistent.

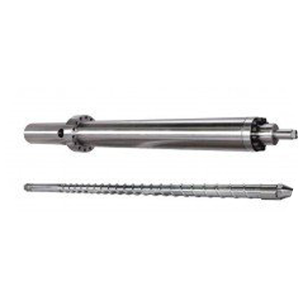

Alternative efficient plasticizing mixing screw, optimization of the injection unt,improve the injection stability and accuracy.

Equipped with electro-hydraulic servo system, the machine is running stable, low noise, high response and energy saving of 25% to 45%.

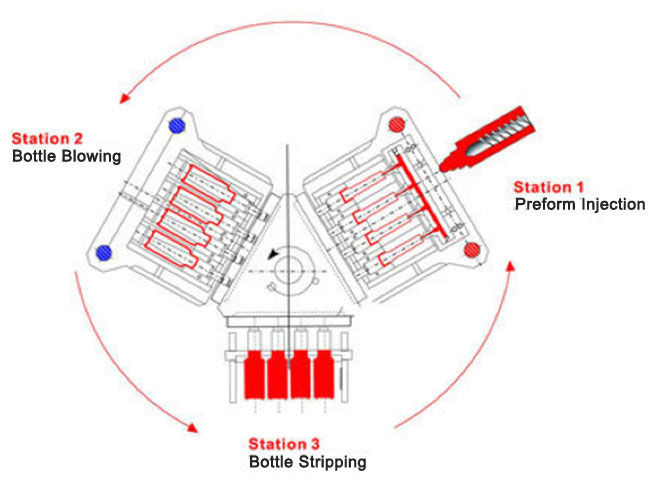

Processing principle

Parameter Table

| Technical Parameters | ||

| Preform system | Unit | MSZ135 |

| Screw diameter | mm | 70 |

| Screw L/D | L/D | 23:1 |

| Shot volume | cm3 | 1077 |

| Injection weight(HDPE) | g | 1020 |

| Max.Screw speed | rpm | 10-235 |

| Heating capacity | KW | 15 |

| No.of heating zone | Qty | 3+N |

| Clamping system | ||

| Clamping force of preform | KN | 1344 |

| Clamping force of blowing | KN | 235 |

| Opening stroke of mold planten | mm | 155 |

| Lifting H of rotary table | mm | 75 |

| Max.Platen size(L×W) | mm | 1400×500 |

| Min.mold thickness(H) | mm | 280 |

| Heating capacity of mould | KW | 10 |

| Stripping system | ||

| Stripping stroke | mm | 260 |

| Dry cycle | sec | 4.5 |

| Driving system | ||

| Motor power | KW | 39.4+39.4 |

| Hydraulic pressure | Mpa | 14 |

| Product range | ||

| Suitable bottle range | ml | 5-800 |

| MAX.bottle height | mm | ≤220 |

| Max.Dia.of bottle | mm | ≤100 |

| Other | ||

| Min.air pressure | Mpa | 1 |

| Discharge rate of compressed air | m3/mm | ≥1.2 |

| Water flowage | m3/h | 6 |

| Total rated power with mold heating | KW | 106.8 |

| Dimension(L×W×H) | M | 6.0×2.5×2.6 |

| Net weinght | ton | 15 |