Product Application

Victor Machinery's injection blow molding machines are suitable for a wide range of plastic bottle production, from 2ml eye drop containers to 2L juice bottles. Our machines are trusted by leading brands in pharmaceutical, cosmetic, food and healthcare industries.

Advantage

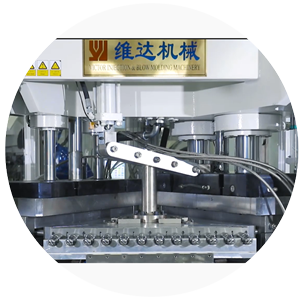

Special designed single crossbar dual-cylinder balance clamping system,for fast opening and closing mold while ensuring uniform distribution.

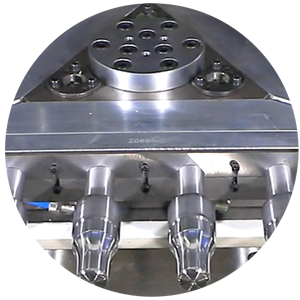

Unique rotating mechanism design, and equipped with automatic lubrication system,ensure rotation precision be consistent.

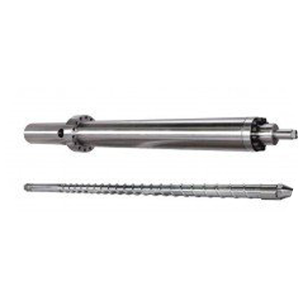

Alternative efficient plasticizing mixing screw, optimization of the injection unt,improve the injection stability and accuracy.

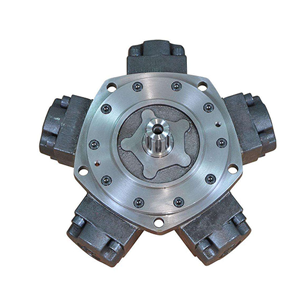

Equipped with electro-hydraulic servo system, the machine is running stable, low noise, high response and energy saving of 25% to 45%.

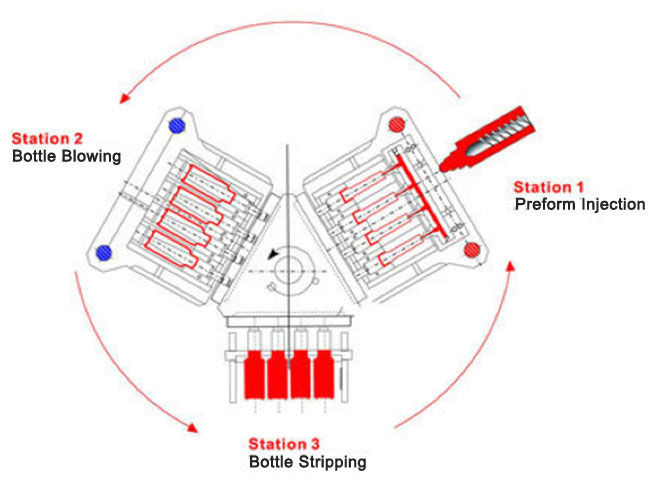

Processing principle

Parameter Table

| Preform system | Unit | MSZ30 | MSZ50H | MSZ50S | MSZ70 | MSZ70S | MSZ95S | MSZ135 |

| Screw diameter | mm | 40 | 50 | 50 | 55 | 55 | 65 | 70 |

| Screw L/D | L/D | 23:1 | 23:1 | 23:1 | 23:1 | 23:1 | 23:1 | 23:1 |

| Shot volume | cm3 | 200 | 392 | 392 | 475 | 475 | 839 | 1077 |

| Injection weight(HDPE) | g | 190 | 372 | 372 | 450 | 450 | 795 | 1020 |

| Max.Screw speed | rpm | 10-225 | 10-235 | 10-235 | 10-235 | 10-235 | 10-235 | 10-235 |

| Heating capacity | KW | 8.3 | 10 | 10 | 10.8 | 10.8 | 12.6 | 15 |

| No.of heating zone | Qty | 3+N | 4+N | 4+N | 3+N | 3+N | 3+N | 3+N |

| Clamping system | ||||||||

| Clamping force of preform | KN | 289.7 | 504 | 528 | 742 | 712 | 1008 | 1344 |

| Clamping force of blowing | KN | 46.7 | 89 | 93.4 | 89 | 107.7 | 221 | 235 |

| Opening stroke of mold planten | mm | 120 | 130 | 165 | 140 | 165 | 155 | 155 |

| Lifting H of rotary table | mm | 65 | 70 | 80 | 70 | 80 | 75 | 75 |

| Max.Platen size(L×W) | mm | 400×270 | 560×390 | 560×390 | 800×390 | 800×390 | 900×480 | 1400×500 |

| Min.mold thickness(H) | mm | 180 | 240 | 240 | 280 | 280 | 280 | 280 |

| Heating capacity of mould | KW | 3 | 3.6 | 3.6 | 6 | 10 | 10 | 10 |

| Stripping system | ||||||||

| Stripping stroke | mm | 220 | 270 | 270 | 240 | 295 | 260 | 260 |

| Dry cycle | sec | 3.5 | 3.5 | 2 | 3.5 | 2.1 | 3 | 4.5 |

| Driving system | ||||||||

| Motor power | KW | 18.2 | 23 | 23 | 39.4 | 31 | 26+26 | 39.4+39.4 |

| Hydraulic pressure | Mpa | 14 | 14 | 14 | 14 | 14 | 14 | 14 |

| Product range | ||||||||

| Suitable bottle volume | ml | 5-800 | 5-800 | 5-800 | 5-800 | 5-800 | 5-800 | 5-800 |

| MAX.bottle height | mm | ≤190 | ≤200 | ≤200 | ≤200 | ≤200 | ≤220 | ≤220 |

| Max.Dia.of bottle | mm | ≤100 | ≤100 | ≤100 | ≤100 | ≤100 | ≤100 | ≤100 |

| Other | ||||||||

| Compressed air pressure | Mpa | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| Compressed air discharge | m3/mm | ≥0.7 | ≥0.7 | ≥0.7 | ≥0.8 | ≥0.8 | ≥1 | ≥1.2 |

| Cooling water flow | m3/h | 3 | 4 | 4 | 5 | 5 | 6 | 6 |

| Total rated power with mold heating | KW | 29.5 | 36.6 | 36.6 | 56.2 | 59 | 75.6 | 106.8 |

| Dimension(L×W×H) | M | 3.56×1.25×2.25 | 4.11×1.57×2.5 | 4.11×1.57×2.5 | 4.1×1.78×2.6 | 4.39×1.91×2.54 | 5.0×2.0×2.6 | 6.0×2.5×2.6 |

| Net weinght | ton | 4 | 5.7 | 5.7 | 9 | 9 | 12 | 15 |