Injection Blow Molded Containers for Travel-Sized Cosmetics: The Perfect Packaging Solution

Introduction

The travel-sized cosmetics market is booming, driven by the growing demand for compact, lightweight, and leak-proof packaging that meets airline regulations and on-the-go lifestyles. Consumers expect durability, convenience, and aesthetic appeal—all while ensuring product integrity.

At [VICTOR MACHINERY], we specialize in high-precision Injection Blow Molding (IBM) technology to manufacture premium travel-sized cosmetic containers. Our IBM process delivers consistent quality, superior leak resistance, and endless customization options, making it the ideal choice for brands in the beauty and personal care industry.

In this article, we explore why Injection Blow Molded containers are the best solution for travel-sized cosmetics and how [VICTOR MACHINERY] can help brands elevate their packaging.

What is Injection Blow Molding (IBM)?

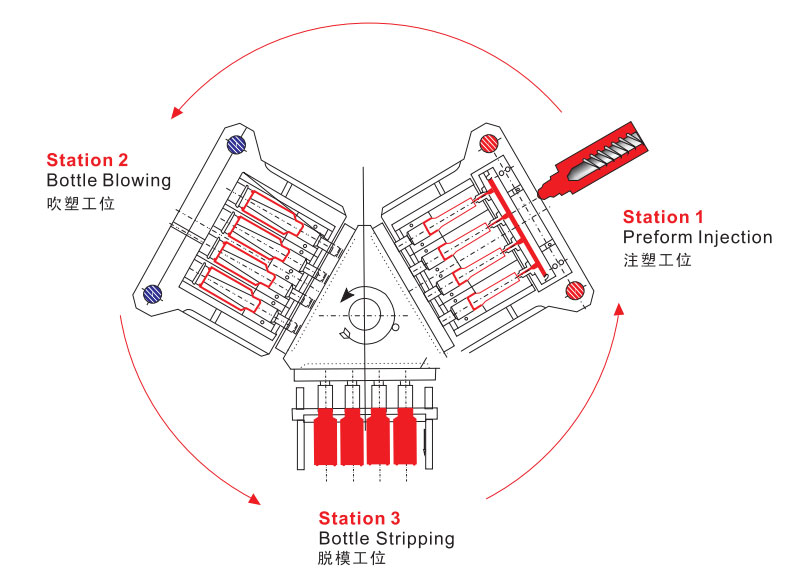

Injection Blow Molding (IBM) is a two-stage manufacturing process that combines injection molding and blow molding to produce hollow, lightweight, and high-strength plastic containers.

How It Works:

-

Injection Molding Phase:

- Molten plastic is injected into a mold to create a preform (a test-tube-like structure with a threaded neck).

- The neck finish (cap threads or snap-fit design) is fully formed at this stage.

-

Blow Molding Phase:

- The preform is transferred to a blow mold, where compressed air expands it into the final container shape.

- The result is a seamless, uniform, and high-clarity bottle or jar.

Why IBM is Superior to Other Molding Techniques

✔ Better Wall Thickness Control – No weak spots, ensuring durability.

✔ Tighter Tolerances – Perfect cap fit for leak-proof security.

✔ Higher Clarity & Smooth Finish – Ideal for premium cosmetics.

✔ More Design Flexibility – Complex shapes, embossing, and branding options.

Why Injection Blow Molded Containers are Ideal for Travel-Sized Cosmetics

1. Leak-Proof & Air-Tight Security

Travel cosmetics must withstand pressure changes in flights, rough handling in luggage, and daily use. IBM ensures:

- Precision-threaded necks for secure cap sealing.

- Consistent wall thickness to prevent cracks or leaks.

- Smooth interior surfaces that prevent product residue buildup.

2. Lightweight Yet Durable

Airline weight restrictions and consumer convenience demand lightweight packaging that doesn’t sacrifice strength. IBM provides:

- Thin but tough walls – Reduces material use while maintaining durability.

- Impact resistance – Withstands drops and rough travel conditions.

3. Compliance with TSA & Airline Regulations

Travel-sized cosmetics must meet 3-1-1 liquid rules (100ml/3.4oz max per container). Our IBM containers are:

- Accurately sized for compliance.

- Designed for easy inspection (transparent options available).

4. Premium Aesthetic Appeal

Brands need packaging that looks luxurious while being functional. IBM allows:

- Crystal-clear plastics (PET, PP) for a high-end look.

- Custom shapes (slim, rounded, square) for brand differentiation.

- Matte, glossy, or metallic finishes.

- Embossed logos, textures, and gradient effects.

5. Cost-Effective for High-Volume Production

IBM is ideal for mass production due to:

- Fast cycle times – High output with minimal waste.

- Lower secondary processing – No additional trimming needed.

- Recyclable materials – Sustainable and cost-efficient.

6. Wide Material Selection for Cosmetic Safety

We use FDA-approved, cosmetic-grade plastics, including:

- PET (Polyethylene Terephthalate) – Ultra-clear, rigid, and recyclable.

- PP (Polypropylene) – Heat-resistant, ideal for creams and serums.

- PE (Polyethylene) – Flexible, used for squeezable tubes.

Applications of IBM in Travel-Sized Cosmetics

[VICTOR MACHINERY] produces a wide range of travel-sized cosmetic containers, including:

✔ Liquids & Serums – Dropper bottles, mini pump bottles.

✔ Creams & Lotions – Jars, squeeze tubes.

✔ Shampoos & Conditioners – Flip-top or screw-cap bottles.

✔ Makeup Products – Lip gloss tubes, foundation bottles.

✔ Sanitizers & Toners – Spray bottles, misters.

Why Choose [VICTOR MACHINERY] for Travel-Sized Cosmetic Packaging?

✔ Industry-Leading Expertise – Decades of experience in IBM for cosmetics.

✔ End-to-End Solutions – From design to mass production.

✔ Eco-Friendly Options – Biodegradable plastics, PCR materials.

✔ Fast Prototyping & Sampling – Speed to market.

✔ Global Supply Chain Support – Reliable logistics.

Conclusion

Injection Blow Molded containers offer the perfect balance of functionality, aesthetics, and compliance for travel-sized cosmetics. At [VICTOR MACHINERY], we combine cutting-edge IBM technology with custom design capabilities to help brands create packaging that stands out on shelves and performs flawlessly on the go.