How Are Pill Bottles Manufactured?

Materials, Processes & Quality Standards

Pill bottles are one of the most common forms of pharmaceutical packaging for tablets, capsules, and other solid-dose medications.

While they may look simple, manufacturing pharmaceutical pill bottles involves far stricter requirements than ordinary plastic containers.

In pharmaceutical packaging, factors such as material safety, dimensional accuracy, cleanliness, and consistency directly affect product quality and regulatory compliance.

This article explains how pill bottles are manufactured, focusing on materials, production methods, and the key quality standards required for pharmaceutical use.

What Are Pill Bottles?

Examples of different pharmaceutical pill bottles commonly used for tablets and capsules in pharmaceutical packaging.

Pill bottles are rigid plastic containers designed to store and dispense solid oral medications such as tablets and capsules. They are widely used across the pharmaceutical industry, including:

- Pharmaceutical manufacturing plants

- Contract packaging facilities

- OTC and prescription drug packaging lines

In practice, pill bottles range from small containers used for high-value prescription medicines to larger bottles commonly seen in OTC and dietary supplement products.

Common Materials Used for Pill Bottles

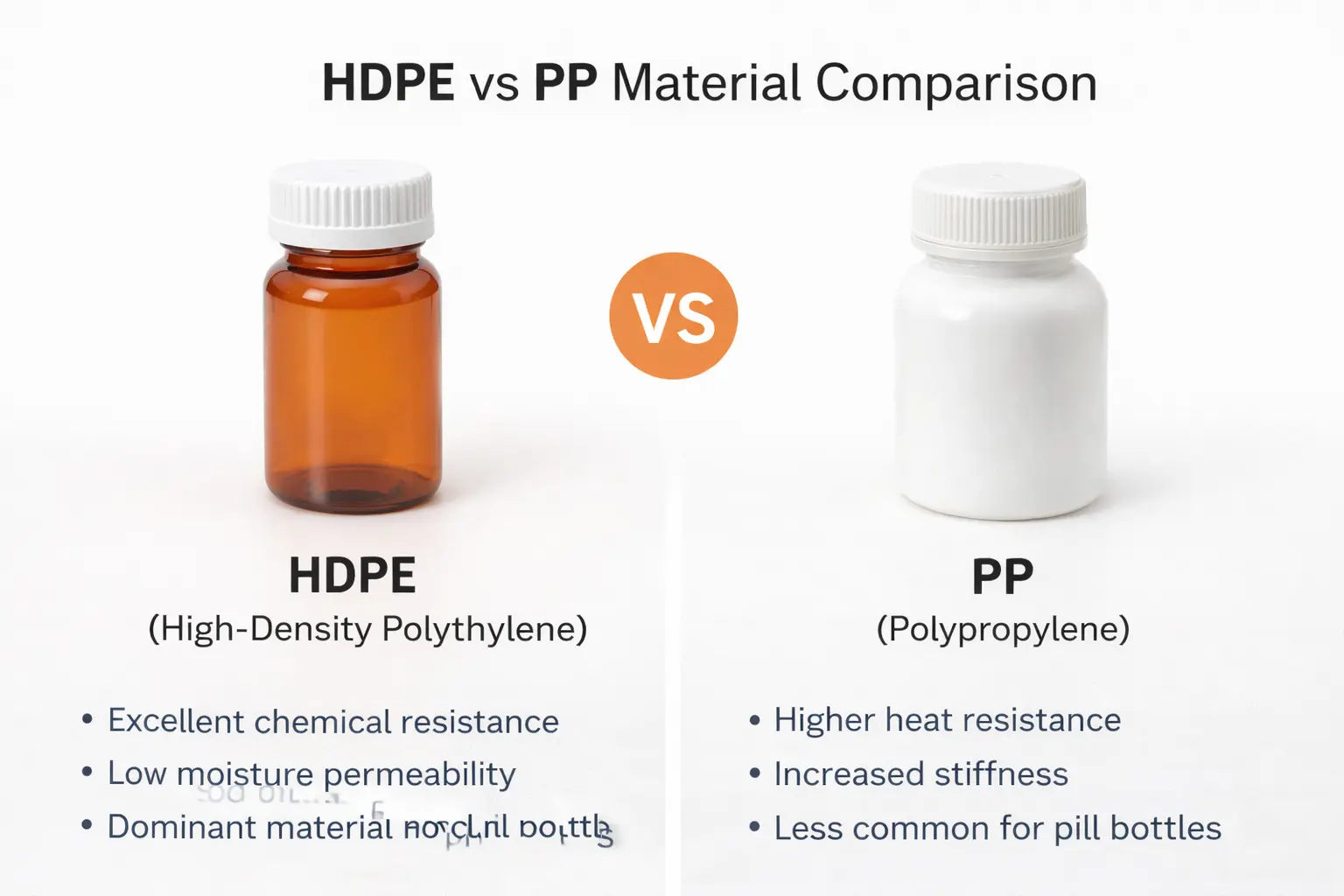

Comparison between HDPE and PP materials commonly used for pharmaceutical pill bottles, highlighting chemical resistance, moisture permeability, and typical applications.

Material selection plays a critical role in pharmaceutical bottle manufacturing. The choice of plastic directly affects moisture protection, chemical resistance, and long-term stability.

HDPE (High-Density Polyethylene)

HDPE is the most widely used material for pill bottles in pharmaceutical packaging. It is preferred because it offers:

- Excellent chemical resistance

- Low moisture permeability

- Good rigidity and impact strength

- Proven safety for pharmaceutical applications

In real production environments, HDPE provides a reliable balance between performance, processability, and cost.

PP (Polypropylene)

PP is used in certain pharmaceutical applications that require:

- Higher heat resistance

- Increased stiffness

However, compared to HDPE, PP is less commonly selected for standard pill bottle production due to processing considerations and material characteristics.

Why PET Is Rarely Used for Pill Bottles

Although PET is widely used for beverage packaging, it is rarely chosen for pill bottles. From a pharmaceutical packaging perspective, PET does not offer the same moisture barrier performance required for solid-dose medications.

Pill Bottle Manufacturing Methods Explained

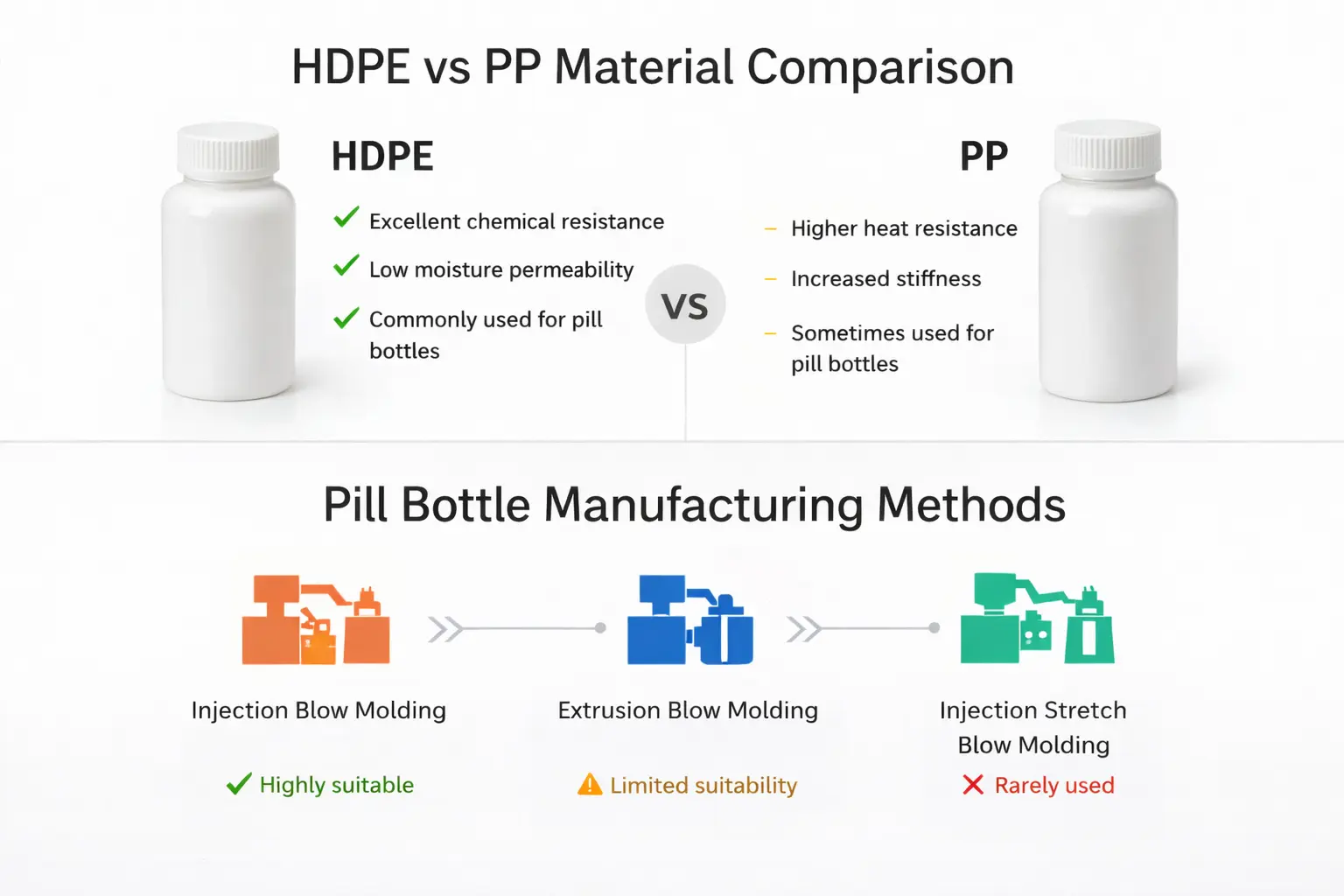

Overview of common pill bottle manufacturing methods, showing the suitability of injection blow molding, extrusion blow molding, and injection stretch blow molding for pharmaceutical packaging.

Several plastic molding technologies are capable of producing hollow containers. However, not every method is suitable for pharmaceutical pill bottles, where dimensional control and cleanliness are critical.

| Manufacturing Method | Suitability for Pill Bottles |

|---|---|

| Injection Blow Molding | ✅ Highly suitable |

| Extrusion Blow Molding | ⚠️ Limited suitability |

| Injection Stretch Blow Molding | ❌ Rarely used |

Among these options, injection blow molding is commonly preferred for small to medium-sized pharmaceutical bottles because it offers better consistency and process control.

For manufacturers evaluating suitable equipment, modern injection blow molding machines are specifically designed to meet pharmaceutical-grade production requirements.

Injection Blow vs Extrusion Blow for Pill Bottles

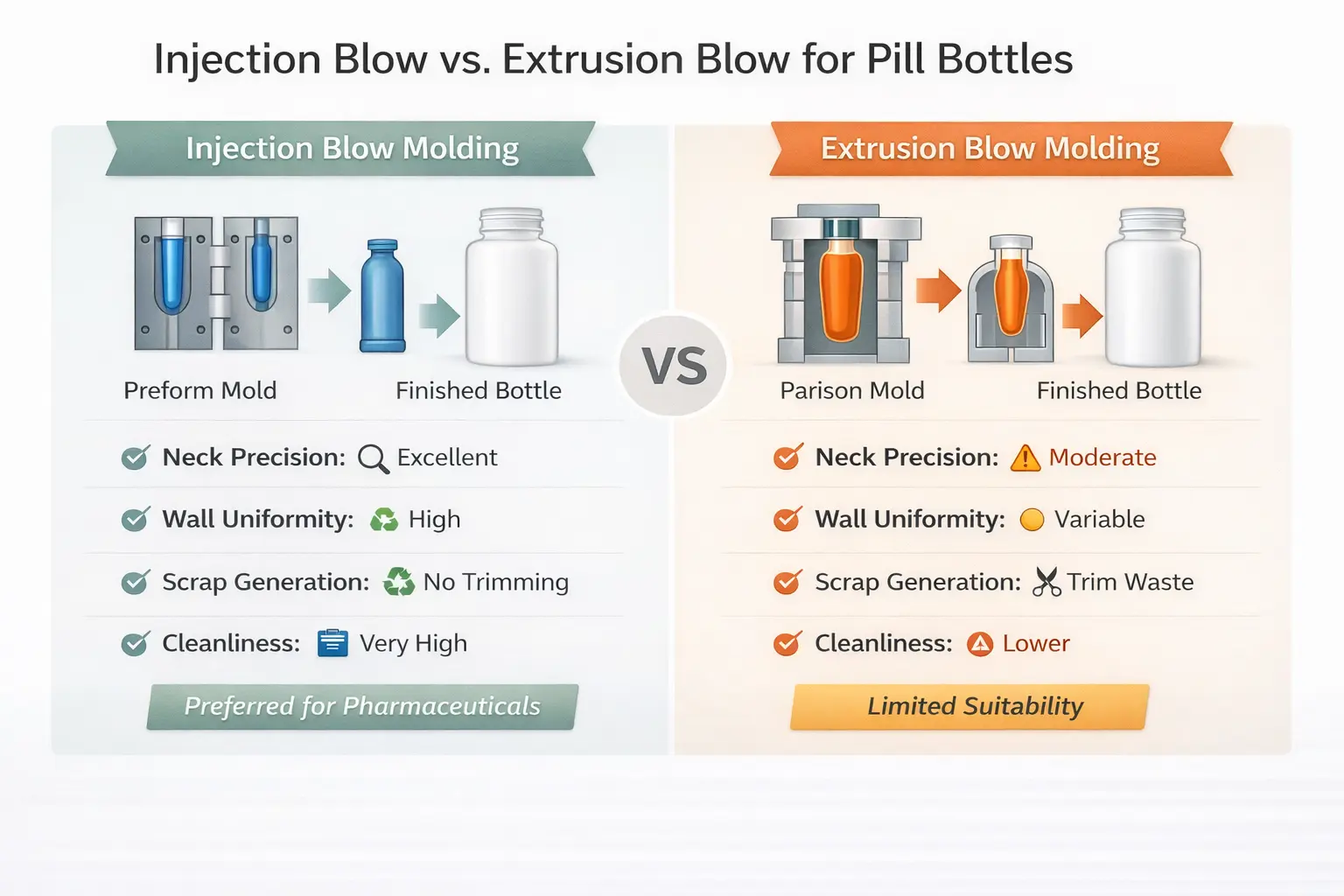

Comparison between injection blow molding and extrusion blow molding for pharmaceutical pill bottle manufacturing, highlighting process precision, material efficiency, and suitability for pharmaceutical packaging.

From a manufacturing perspective, the choice between injection blow molding and extrusion blow molding has a direct impact on bottle quality, cleanliness, and long-term production stability.

| Criteria | Injection Blow Molding | Extrusion Blow Molding |

|---|---|---|

| Neck finish accuracy | Excellent | Moderate |

| Wall thickness uniformity | High | Variable |

| Scrap generation | None | Trimming required |

| Cleanliness | Very high | Lower |

| Suitability for pharma | Ideal | Limited |

For pharmaceutical manufacturers requiring high neck precision, clean production, and long-term dimensional stability, injection blow molding machines are often selected as the core equipment in pill bottle production lines.

You can explore a full range of pharmaceutical-grade injection blow molding machines here.

Injection Blow Molding Process for Pill Bottles

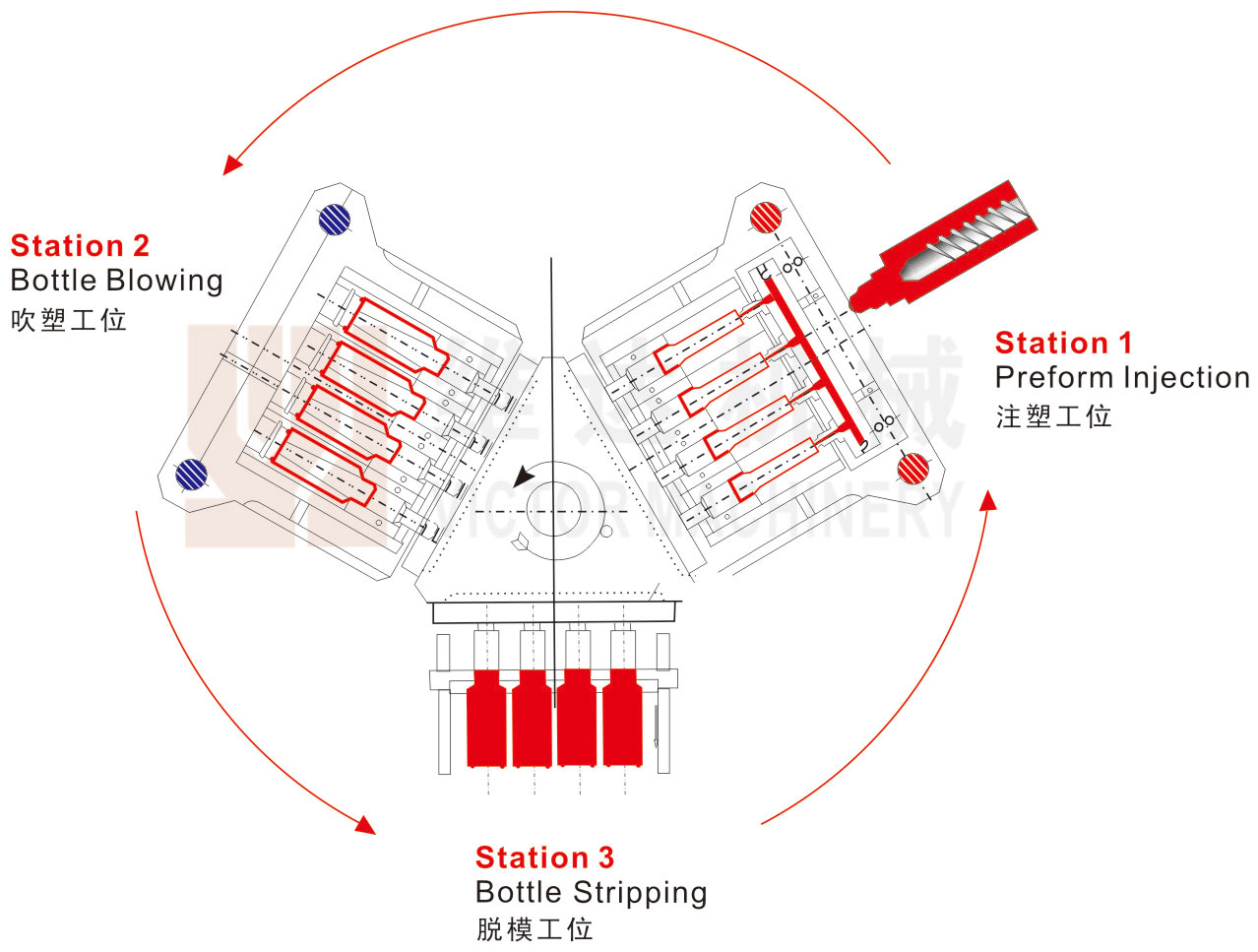

Injection Blow Molding Process for Pharmaceutical Pill Bottles

Video demonstration of the injection blow molding process used for manufacturing pharmaceutical pill bottles.

Injection blow molding process diagram showing the key stages involved in pharmaceutical pill bottle production.

Injection blow molding combines injection molding and blow molding into a single, continuous process designed for precision containers.

- Injection Stage – Molten plastic is injected into a mold to form a preform with a precise neck finish.

- Blowing Stage – The preform expands inside the blow mold using compressed air.

- Cooling and Ejection – Bottles are ejected without trimming or secondary processing.

This integrated process is implemented on dedicated injection blow molding machines engineered for pharmaceutical packaging, where process stability and repeatability are critical.

Learn more about available injection blow molding machine solutions for pharmaceutical bottle manufacturing.

Key Quality Requirements for Pharmaceutical Pill Bottles

Meeting these quality requirements depends not only on materials and molds, but also on the performance of the injection blow molding machine used in production.

Modern pharmaceutical-grade injection blow molding machines are designed to support consistent quality control and clean manufacturing environments.

Dimensional Accuracy

Precise neck finishes are essential to ensure reliable sealing with caps and closures.

Uniform Wall Thickness

Consistent wall thickness helps maintain mechanical strength and prevents deformation during filling, capping, and transportation.

Clean Production Environment

In pharmaceutical packaging, trimming scrap or secondary contamination is unacceptable. Clean, controlled production is critical.

Material Compliance

Plastic materials must comply with pharmaceutical and food-contact regulations in target markets.

Common Defects in Pill Bottle Production and How to Avoid Them

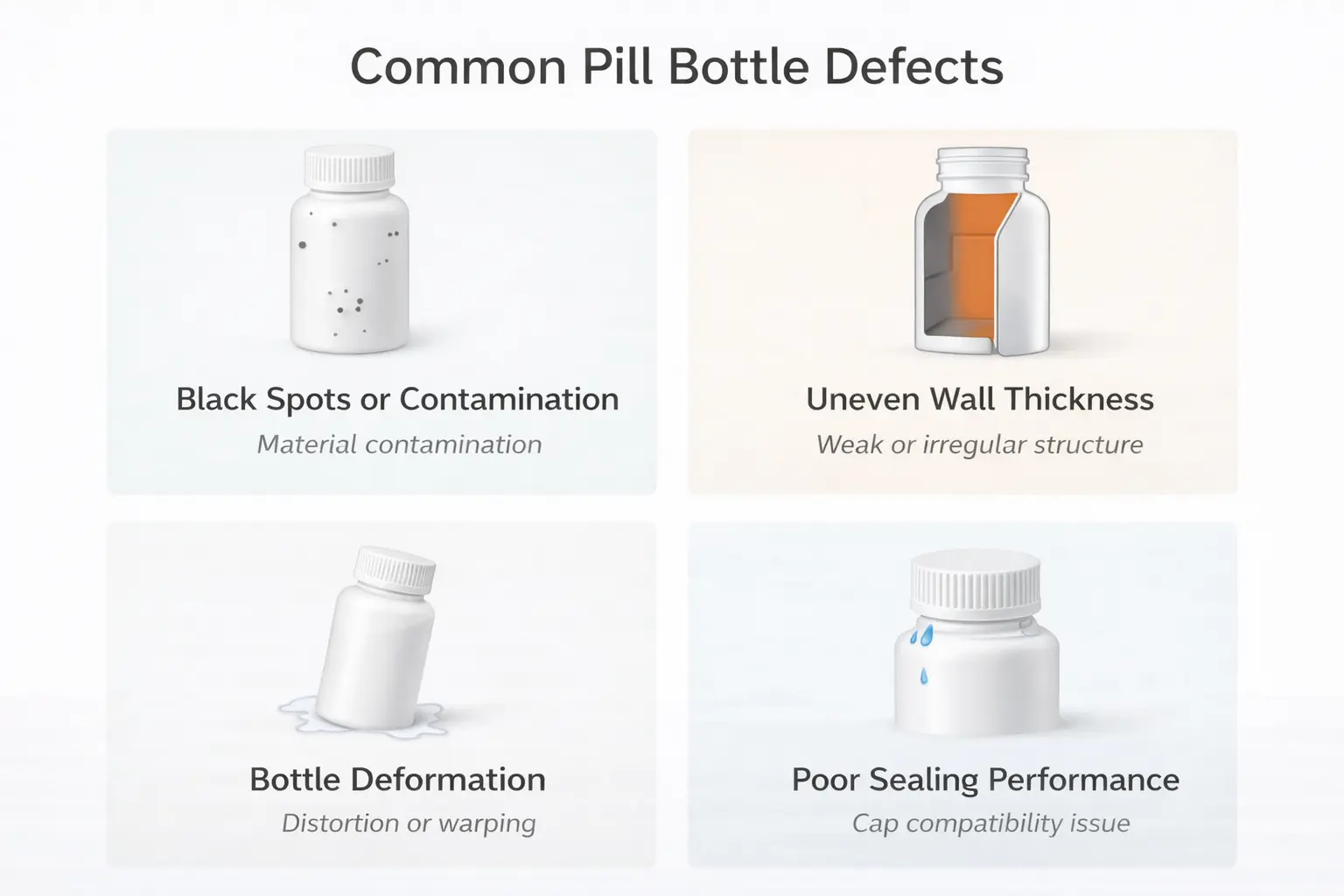

Common defects observed in pharmaceutical pill bottle production.

Even small defects can result in product rejection or regulatory issues, including:

- Black spots or material contamination

- Uneven wall thickness

- Bottle deformation

- Poor sealing performance

These issues are typically minimized through proper process control, mold design, and correct equipment selection.

Typical Applications of Pill Bottles

Injection blow molded pill bottles are widely used for:

- Tablets

- Capsules

- OTC medicines

- Dietary supplements

These applications require consistent bottle dimensions and reliable sealing performance across large production volumes.

How to Choose the Right Manufacturing Process for Pill Bottles

When selecting a manufacturing process for pill bottles, pharmaceutical manufacturers typically consider:

- Bottle size and required production output

- Material compatibility (HDPE or PP)

- Cleanroom or GMP-related requirements

- Long-term quality consistency

In many pharmaceutical projects, process stability and dimensional accuracy are prioritized over maximum output.

Conclusion

Pill bottles are manufactured using specialized processes designed to meet pharmaceutical-grade quality and safety requirements.

Among available technologies, injection blow molding provides excellent dimensional control, cleanliness, and consistency, making it a widely used solution for pharmaceutical pill bottle production.

Looking for a Reliable Manufacturing Solution for Pharmaceutical Pill Bottles?

If you are planning or upgrading a pharmaceutical bottle production line, selecting the right equipment is critical.

Explore our full range of injection blow molding machines designed for pharmaceutical pill bottle manufacturing, or contact our engineering team for technical consultation.