How to Integrate IML (In-Mold Labeling) with Injection Blow Molding

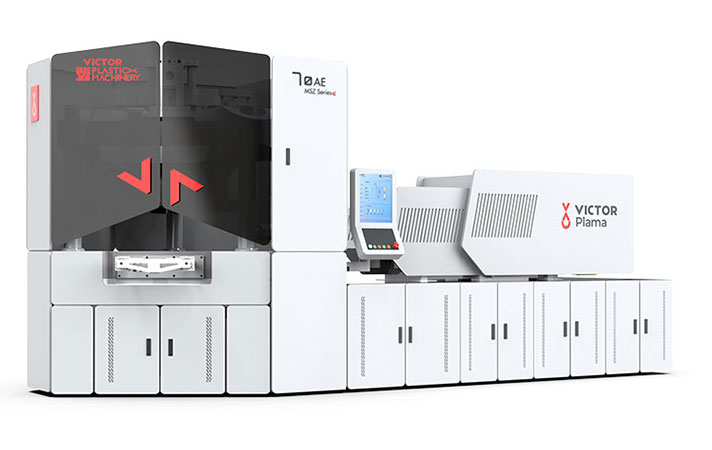

At VICTOR MACHINERY, we understand that premium packaging demands precision, durability, and flawless aesthetics—which is why integrating In-Mold Labeling (IML) with Injection Blow Molding is a game-changing solution for brands that refuse to compromise. This advanced process combines the structural integrity of blow-molded containers with the high-end, long-lasting appeal of embedded labels, all in a single, efficient production cycle. The result? Sleek, tamper-proof packaging that stands out on the shelf and withstands the test of time.

The magic happens when a pre-printed label is placed inside the mold before injection. As molten plastic fills the cavity, it fuses seamlessly with the label, creating a smooth, scratch-resistant surface that won’t peel, crack, or fade. No adhesives, no secondary processes—just perfectly integrated branding that enhances both functionality and visual impact. At VICTOR MACHINERY, we leverage cutting-edge robotic systems and precision-engineered molds to ensure every label is positioned with micrometer accuracy, eliminating defects and maximizing consistency.

Why choose this method? Because it’s smarter, faster, and more sustainable. Traditional labeling adds extra steps and materials, but IML with injection blow molding streamlines production, reducing waste and costs while delivering superior quality. Whether you’re in cosmetics, pharmaceuticals, food & beverage, or specialty chemicals, this technology ensures your packaging reflects the excellence of your product.

Partnering with VICTOR MACHINERY means access to expert engineering and end-to-end support—from label design to mold optimization. Our team works closely with you to tailor the process for your specific needs, ensuring flawless execution from prototype to mass production.

Elevate your packaging with VICTOR MACHINERY’s IML-integrated injection blow molding solutions—where innovation meets perfection. Let’s create something extraordinary together.