PP vs HDPE vs PET: Which Material Performs Best in IBM?

When selecting the right material for industrial applications, the choice often comes down to three widely used polymers: PP, HDPE, and PET. Each has distinct properties that determine its suitability for demanding environments. Polypropylene (PP) is known for its balance of strength, flexibility, and chemical resistance, making it an excellent candidate for containers, automotive parts, and reusable packaging. It withstands moderate temperatures and resists fatigue, which allows it to perform reliably in dynamic settings. However, its limitations become apparent in extremely high-temperature or high-impact scenarios, where other materials might prove more durable.

High-density polyethylene (HDPE), on the other hand, offers superior impact resistance and moisture barrier properties. It is lightweight yet tough, often used in applications ranging from chemical storage tanks to food-grade bottles. HDPE performs exceptionally well in cold temperatures and resists many solvents, but it is less rigid than PET and can deform under sustained high heat. For industries that prioritize durability in variable climates and need strong, weldable materials, HDPE remains a versatile and cost-effective option.

High-density polyethylene (HDPE), on the other hand, offers superior impact resistance and moisture barrier properties. It is lightweight yet tough, often used in applications ranging from chemical storage tanks to food-grade bottles. HDPE performs exceptionally well in cold temperatures and resists many solvents, but it is less rigid than PET and can deform under sustained high heat. For industries that prioritize durability in variable climates and need strong, weldable materials, HDPE remains a versatile and cost-effective option.

PET stands out with its exceptional clarity, rigidity, and gas barrier qualities. It is the material of choice for beverage bottles, food trays, and transparent packaging where product visibility and shelf life are critical. PET also boasts strong mechanical performance under stress and high recyclability, aligning with modern sustainability goals. Nevertheless, it is more susceptible to heat distortion compared to PP and HDPE, which can limit its use in hot-fill or high-temperature sterilization processes without special treatment or additives.

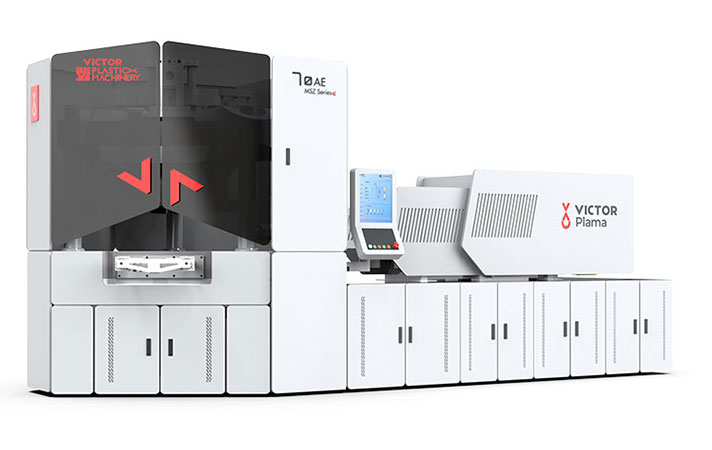

So, which material performs best in an industrial context? The answer depends entirely on the specific demands of your application. If chemical resistance and flexibility are paramount, PP is often the ideal choice. For impact resistance and moisture protection, especially in cooler environments, HDPE excels. When transparency, stiffness, and gas barriers are non-negotiable, PET leads the way. At VICTOR, we help you navigate these choices with precision, offering tailored material solutions that enhance performance, sustainability, and value. Let us partner with you to select the polymer that doesn’t just meet standards—it defines them.