Types of Bottles Suitable for Injection-Blow Molding (IBM)

Choosing the right bottle design is essential for achieving consistent quality in injection-blow molding (IBM). Bottle size, material, wall thickness, and structural design all influence production stability, mold performance, and final product appearance.

Injection-blow molding is best suited for small-to-medium bottles (5ml–1L) made from materials such as HDPE, PP, PET, and PETG, offering superior dimensional accuracy and uniform wall distribution.

IBM technology is widely used for pharmaceutical, cosmetic, food, and household chemical packaging, where precision and cleanliness are critical.

Learn more about the process here:

➡️ How the IBM Process Works

What Types of Bottles Are Ideal for the Injection-Blow Molding Process?

Not all bottle shapes or materials are suitable for IBM. This process performs best with thermoplastics that allow stable preform formation, and bottle designs that support uniform inflation inside the blow mold.

Most IBM-compatible bottles are small-to-medium in volume, require high dimensional precision, and demand excellent neck accuracy.

If you're looking to produce these bottle types, explore Victor’s full IBM lineup:

➡️ Injection-Blow Molding Machines

Common Bottle Types for IBM

| Bottle Type | Material | Typical Uses | Key Advantages |

|---|---|---|---|

| Pharmaceutical Bottles | PET, HDPE | Eye drops, syrups, vitamins | High clarity, precise neck finish |

| Cosmetic Bottles | PET, PP | Serums, lotions, skincare | Aesthetic finish, great transparency |

| Beverage Bottles | PET | Juice shots, small drinks | Lightweight, impact resistant |

| Food Containers | HDPE, PP | Sauces, condiments | Leak-proof, food-grade durability |

For more bottle design insights, read:

➡️ Design Requirements for IBM Bottles

What Are the Wall Thickness Requirements for IBM Bottles?

Wall thickness determines strength, weight, and barrier performance. Incorrect thickness can lead to deformation, cracking, or excessive material consumption.

IBM bottles typically have a wall thickness range of 0.25mm–2mm.

Key IBM Bottle Design Considerations

-

Uniform Wall Distribution

Ensures consistent strength and prevents warping or weak areas. -

Accurate Neck Finish

Supports standard closures such as CRC, droppers, pumps, and screw caps. -

Stable Base Design

Affects standing stability and impact resistance. -

Material Flow Optimization

Prevents shrinkage and internal stress concentration.

Need help with mold optimization?

➡️ Contact Victor Machinery’s Engineering Team

What Are the Common Size Specifications for IBM Bottles?

IBM is generally used to manufacture small and medium-sized bottles for industries with strict dimensional requirements.

Standard IBM bottle dimensions:

- Volume: 5ml–1L

- Height: 50mm–300mm

- Diameter: 20mm–100mm

Typical Industry Bottles

| Industry | Common Sizes | Examples |

|---|---|---|

| Pharmaceuticals | 10ml, 30ml, 100ml | Eye drops, syrups |

| Cosmetics | 50ml, 100ml, 250ml | Skincare, serum bottles |

| Food & Beverage | 250ml, 500ml, 1L | Juice, sauces |

For machine compatibility, check:

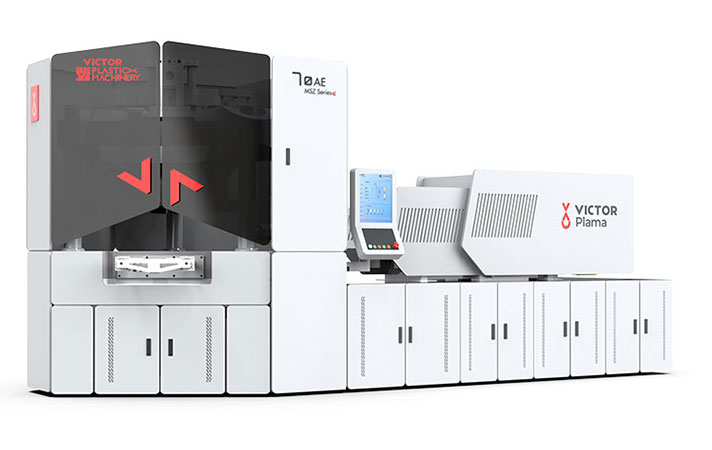

➡️ MSZ Series Injection-Blow Machines

What Are the Key Design & Testing Points for IBM Bottles?

Even the best-designed bottle must undergo proper testing to ensure safety and functionality.

Essential Testing Procedures

- Drop Test

- Leak Test

- Thermal Resistance Test

- Material Compatibility Test

Testing guarantees performance in real-world conditions and reduces the risk of defects during mass production.

Conclusion

Injection-blow molding is highly effective for producing durable, precise, and visually appealing bottles.

With correct design and testing, manufacturers can achieve:

- Stable production

- Low defect rates

- High-quality packaging

- Enhanced market competitiveness

Explore Victor’s IBM machine range:

👉 View All IBM Models →

📚 Recommended Reading (Related Articles)

Enhance your IBM knowledge with these articles:

- How Three-Station IBM Machines Work

- Applications of IBM Technology in Medical Packaging

- Energy-Saving Innovations in IBM Systems

- Types of Bottles Made by IBM (Overview)