Three-Station IBM Process Explained: How Injection-Blow Molding Ensures Precision & Stability

Updated in October 2025

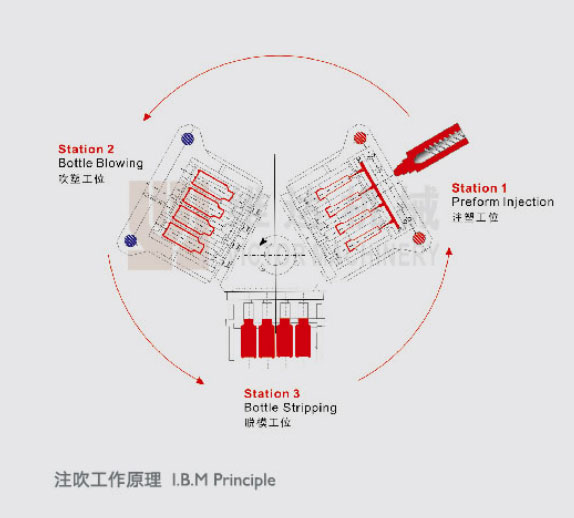

Understanding how the three-station IBM (Injection-Blow Molding) process works is essential for anyone involved in plastic packaging manufacturing. This technology integrates injection molding, blow molding, and stripping into one continuous cycle, making it one of the most stable and precise methods for producing small and medium-sized HDPE/PP bottles.

Below is a clear and professional explanation of how the IBM process works and why it is preferred in cosmetics, pharmaceuticals, daily chemical packaging, and laboratory containers.

What Is the Three-Station IBM Process?

The IBM system consists of three synchronized stations positioned at 120° intervals on a rotary table:

- Injection – forming the high-precision preform

- Blowing – inflating the preform into its final shape

- Stripping – ejecting the finished bottle

This continuous rotation allows each mold to complete one step per cycle, resulting in high output, excellent dimensional stability, and zero-flash bottle production.

For a complete list of IBM machines, visit:

👉 Victor IBM Machine Catalog →

Station 1: Injection – Forming the Preform with High Accuracy

At the first station, molten plastic is injected into a preform mold. Servo-driven plasticizing and temperature balance ensure:

- Highly accurate neck finish

- Uniform wall thickness

- Perfect sealing with the core rod

- No flash trimming needed

Industries that rely on neck precision include:

- Pharmaceutical bottles

- Cosmetic lotion & skincare packaging

- Glue bottles

- Laboratory reagent bottles

Machine shown: Victor MSZ50S IBM Machine

👉 View MSZ50S Model →

Station 2: Blow Molding – Expanding the Preform Into Its Final Shape

After injection, the preform rotates 120° to the blowing station. Here:

- The blow mold closes

- Compressed air enters through the core rod

- The preform expands inside the bottle cavity

The blow station provides:

- Stable and uniform material distribution

- Smooth bottle appearance

- High shape & dimensional consistency

- Perfect repeatability in multi-cavity production

For more comparisons, see:

👉 Injection Blow Molding vs Extrusion Blow Molding

Station 3: Stripping – Ejecting the Finished Bottle Smoothly

The final 120° rotation brings the bottle to the stripping station.

A stripper mechanism:

- Pushes the finished bottle off the core rod

- Ejects it without scratches or deformation

- Transfers bottles onto a conveyor for cooling

This ensures shorter cycle time and high productivity.

Why the Three-Station IBM Process Is Superior

The IBM process is ideal for industries requiring precision, hygiene, and stable dimensional control.

| Advantage | Explanation |

|---|---|

| Perfect neck accuracy | Injection-molded neck ensures tight tolerances for caps & droppers |

| Uniform wall thickness | Hot-parison blowing provides consistent distribution |

| High dimensional stability | Suitable for medical, cosmetic, and laboratory-grade bottles |

| Zero flash | No trimming or secondary work is needed |

| Wide material compatibility | PE, PP, PETG, PS, COC, TPU, PLA, and more |

| High efficiency | Continuous rotary production improves output significantly |

Learn more about IBM solutions:

👉 Victor IBM Solutions →

Industries That Rely on the IBM Process

- Eye-drop bottles

- Nasal spray containers

- Cosmetic lotion & serum bottles

- Personal care packaging

- Laboratory reagent bottles

- Industrial glue bottles

- Small food-grade containers

For application-specific machine recommendations:

👉 Contact Victor Technical Team →

Conclusion

The three-station IBM process—Injection → Blow → Strip—is one of the most advanced and precise methods for manufacturing small and medium plastic bottles. Its outstanding accuracy, stability, and efficiency make it the preferred choice for industries that require high-standard packaging quality.

🔍 Recommended Reading — Injection Blow Molding Expertise

To deepen your understanding of IBM technology and help you select the right machine for your production needs, here are important technical resources from Victor Machinery:

1. Injection Blow Molding vs Extrusion Blow Molding – Full Comparison

A complete comparison of IBM and EBM in precision, cycle stability, bottle finishing, and energy consumption.

👉 https://www.victorcn.com/injection-blow-molding-vs-extrusion-blow-molding/

2. How Core Rod Technology Affects Bottle Quality in IBM Machines

Understand why the core rod is the “heart” of IBM and how it impacts wall thickness, uniformity, and bottle strength.

👉 https://www.victorcn.com/core-rod-technology-injection-blow-molding/

3. What Type of Bottles Are Best for Injection Blow Molding?

A detailed guide to the most suitable bottle types, materials, and applications for IBM production.

👉 https://www.victorcn.com/types-of-bottles-made-by-injection-blow-molding-best-applications-explained/

🏭 Recommended Victor IBM Machines

Looking for the right IBM equipment? Start with our featured high-precision model or explore the full catalog.

MSZ50S – High Precision Injection Blow Molding Machine

Ideal for medical, cosmetic, laboratory, and pharmaceutical bottles requiring high dimensional accuracy.

👉 https://www.victorcn.com/products/injection-blow-molding-machine/msz50s-injection-blow-molding-machine/

Full IBM Machine Catalog

Browse our complete lineup of IBM machines for PE/PP/PETG bottle manufacturing.

👉 https://www.victorcn.com/products/injection-blow-molding-machine/

📩 Need Technical Advice?

If you need guidance on choosing the right IBM machine — based on your bottle size, material, production output, or mold requirements — our engineers are ready to assist.

👉 Contact Victor Technical Team

https://www.victorcn.com/contact/