Why Injection Blow Molding Is the Top Choice for Household Chemical Packaging

Every day, millions of bottles are trusted to safely hold powerful household chemicals—but not all packaging technologies deliver the same safety, durability, or precision. When a bottle fails, the risk extends far beyond a simple leak. This is why choosing the right packaging method is critical.

Injection blow molding (IBM) stands out as the most reliable process for producing strong, seamless, and dimensionally accurate plastic bottles for household chemical applications. It ensures superior safety, enhances brand value, and reduces long-term manufacturing costs.

Most consumers use these bottles without thinking twice, yet the engineering behind them dramatically impacts product protection, shelf appeal, and profitability. Let’s explore why IBM is the leading technology for this sector, and the advantages it brings to chemical packaging.

Superior Sealing Performance and Chemical Resistance for Safe Storage

A leaking bleach bottle isn’t just inconvenient—it's dangerous. Traditional bottle-making methods can introduce weak points that fail under pressure or react to chemical exposure. IBM, however, delivers exceptional leak resistance and long-term chemical stability.

What makes IBM so safe is the precision of its injection-molded neck finish and its seamless, one-piece structure. Because the neck is injection molded before blowing, it maintains perfect dimensions that ensure a hermetic seal against even the most aggressive chemical formulations.

How IBM Ensures Safety and Reliability

IBM’s enhanced safety comes from three engineering advantages:

1. A Two-Stage, High-Precision Process

The bottle begins as an injection-molded preform where the neck—including threads—is fully formed with exact accuracy. The preform then moves to the blow mold, where it’s inflated into the final shape without distorting the neck. This preserves perfect thread geometry for leak-proof sealing.

2. Chemical-Resistant Material Selection

Resins such as HDPE and PP are commonly used for household chemicals because they are chemically inert. They resist acids, alkalis, solvents, and oxidizers, ensuring the packaging does not degrade or contaminate the product.

3. Superior Structural Integrity

The seamless, one-piece IBM design eliminates weld lines and weak spots. Consistent wall thickness prevents collapse, bursting, or permeation. This structural reliability minimizes storage and transport risks.

| Feature | Injection Blow Molding (IBM) | Extrusion Blow Molding (EBM) |

|---|---|---|

| Neck Precision | Very high, no trimming required | Lower, trimming may cause leaks |

| Seal Integrity | Excellent, hermetic | Good but more variable |

| Chemical Resistance | Excellent | Good, depends on finish quality |

| Overall Safety | Superior and consistent | Good, with more variability |

IBM is a foundational part of risk management for chemical brands. It protects consumers, preserves product performance, and safeguards brand reputation.

High-Precision Molding and Integrated Structure for Premium Brand Appearance

In the crowded household chemical market, packaging is often the first signal of product quality. A well-designed, high-precision bottle can elevate brand perception and influence purchasing decisions long before a consumer reads the label.

IBM’s precision molding delivers outstanding visual and tactile quality. Smooth surfaces, sharp details, and consistent geometry create a premium feel that instantly differentiates your product on the shelf.

Precision Molding Advantages That Strengthen Branding

1. Flawless Surface Finish

The blow mold's mirror-polished interior creates bottles with glossy, uniform surfaces free of weld lines. This makes IBM containers ideal for high-resolution printing, shrink sleeves, or premium labeling.

2. Greater Design Freedom

IBM easily forms bottles with complex panel designs, ergonomic curves, and textured grips. These features improve usability and enhance brand recognition—especially important for high-frequency household use.

3. One-Piece Integrated Construction

Because the bottle is formed as a single unit, there are no glued necks, seams, or weak joints. Consumers perceive these bottles as stronger and more reliable, reinforcing product trust and allowing brands to command higher price points.

Packaging doesn’t just hold a product—it communicates brand values. IBM offers the precision and aesthetics required to stand out in a competitive consumer market.

Efficient Mass Production and Material Control That Reduce Packaging Costs

Premium performance doesn’t have to come with premium manufacturing costs. IBM delivers cost efficiency through reduced material waste, high-speed automation, and smoother downstream production.

Understanding the True Cost Advantages of IBM

1. Near-Zero Material Waste

IBM is a net-shape process. Preforms are designed with the exact amount of resin needed for each bottle, eliminating parison trimming and reducing regrind. This directly lowers material consumption and cost.

2. High-Speed, Stable Automation

Rotary IBM systems can produce thousands of identical bottles per hour. High repeatability reduces QC overhead and minimizes defective goods.

3. Cost Savings in Downstream Operations

The perfect neck finish ensures smooth high-speed filling and capping, minimizing line stoppages and mechanical jams. Stronger bottle structure also reduces shipping damage and product loss.

| Cost Factor | Injection Blow Molding (IBM) | Extrusion Blow Molding (EBM) |

|---|---|---|

| Material Waste | Very low, net shape | Higher, requires trimming |

| Production Speed | Very high | High, but less consistent |

| Labor Requirement | Low (highly automated) | Moderate (trimming often needed) |

| Filling Line Performance | Excellent | More downtime from neck defects |

When total cost of ownership is considered—from resin usage to filling-line operation—IBM consistently provides lower overall cost per finished product. It’s a smart, scalable choice for chemical brands focused on sustainable growth.

Conclusion

Injection blow molding leads the household chemical packaging industry because it integrates safety, premium appearance, and long-term cost efficiency in one process. Whether for bleach, detergents, disinfectants, or specialty cleaners, IBM provides the performance and reliability required for demanding chemical applications.

📌 Recommended Resources for Household Chemical Packaging

To deepen your understanding of IBM applications in the household chemical industry, explore these related resources:

-

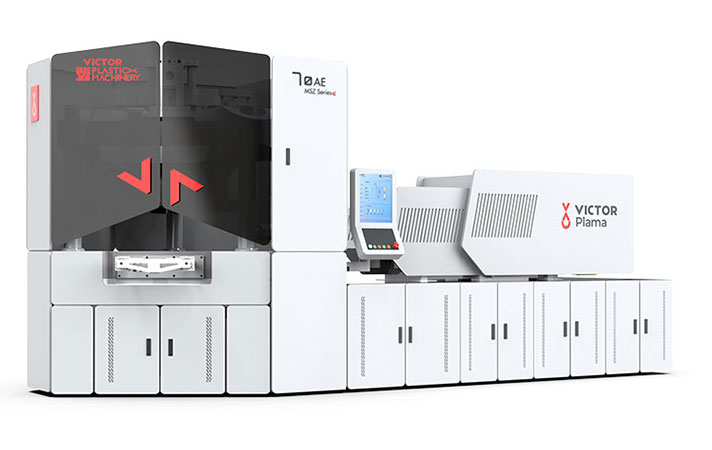

👉 Injection Blow Molding Machines

Explore IBM systems optimized for detergent bottles, bleach containers, and chemical-resistant packaging. -

👉 Types of Bottles Suitable for Injection Blow Molding

Learn which bottle shapes and materials are most effective for chemical products. -

👉 How Three-Station IBM Machines Work

Understand how injection, blowing, and stripping create high-strength, leak-proof bottles. -

👉 Energy-Saving Innovations in IBM Systems

See how modern IBM systems reduce operational costs for large-scale chemical packaging lines.