- Unlocking Design Freedom: The Capabilities of IBM for Complex Geometries

- Overcoming Manufacturing Bottlenecks: IBM for Ergonomic and Brand-Distinctive Containers

- From Mold to Market: Streamlining the Production of Intricate Packaging with IBM

How Can Injection Blow Molding Create Complex Shapes in Packaging?

Many brands struggle with packaging design limitations. These constraints frustrate creativity and reduce market impact. Injection blow molding solves this by enabling intricate, custom shapes.

Injection blow molding creates complex packaging shapes by injecting molten material into a mold, then blowing it into the final form. This process ensures high precision, uniform wall thickness, and extensive design flexibility for modern bottles and containers. It is ideal for mass production while maintaining consistency and reducing waste.

If you're new to molding technologies, here are useful background references:

- Blow Molding (Wikipedia): https://en.wikipedia.org/wiki/Blow_molding

- Injection Molding (Wikipedia): https://en.wikipedia.org/wiki/Injection_moulding

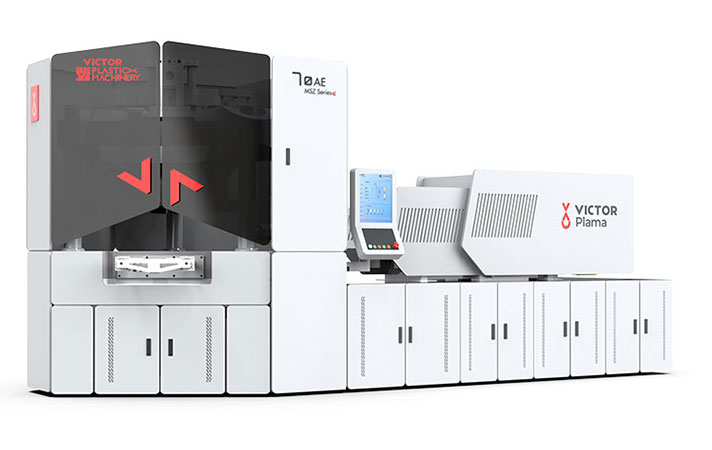

For more about who we are, visit Victor Machinery.

Now, let's dive into the specific ways this technology transforms packaging design and manufacturing.

How Can IBM Unlock Design Freedom for Complex Geometries?

Designers often face rigid manufacturing limits. These restrictions kill innovation and lead to generic packaging.

Injection Blow Molding (IBM) breaks these barriers, allowing unprecedented creative expression.

IBM unlocks design freedom by supporting undercuts, sharp angles, and textured surfaces in a single molded piece.

The mold defines the shape precisely, so complex geometries are achievable without extra assembly.

To understand IBM’s shaping process in detail, you may refer to:

👉 IBM Process Overview

https://www.victorcn.com/products/injection-blow-molding-machine/injection-blow-molding-process/

Exploring the Technical Capabilities

Injection blow molding offers several advantages for complex geometries.

1. Precision in Detail Formation

The injection step captures fine details accurately. Then the blowing stage expands the material evenly, producing shapes other methods cannot match.

2. Material Versatility

IBM works with PET, PP, and other popular packaging materials.

Learn more about IBM’s performance with different resins here:

👉 Injection Blow Molding vs Extrusion Blow Molding

https://www.victorcn.com/injection-blow-molding-vs-extrusion-blow-molding/

3. High Repeatability in Mold Production

IBM molds can produce thousands of identical pieces. This ensures brand consistency and reliable container performance.

4. Challenges to Consider

Complex shapes require sophisticated molds and design expertise. Although costlier upfront, the long-term output efficiency often outweighs the investment.

Comparison of IBM vs Other Methods

| Feature | Injection Blow Molding | Extrusion Blow Molding | Injection Molding |

|---|---|---|---|

| Shape Complexity | High – supports undercuts & details | Moderate | High, but not for hollow parts |

| Wall Thickness | Very uniform | Less controlled | Uniform (solid parts) |

| Production Speed | Fast, efficient | Fast but may need trimming | Fast but not suitable for bottles |

| Material Usage | Minimal waste | More trimming waste | Efficient for solids |

This level of control enables packaging engineers and brand designers to unlock far more creative shapes than traditional molding processes.

How Does IBM Overcome Manufacturing Bottlenecks for Ergonomic and Brand-Distinctive Containers?

Production bottlenecks delay launches and increase costs.

Injection blow molding overcomes these issues by integrating shaping and finishing in one automated cycle.

Addressing Common Production Challenges

1. Ergonomic Designs

Soft curves and grip shapes can be molded directly—ideal for personal care, cosmetics, and household bottles.

2. Brand-Distinctive Containers

Logos, embossed text, and structural brand elements can be molded directly into the bottle.

3. Waste Reduction

The process uses the exact required amount of material and produces minimal scrap.

4. Consistency

IBM achieves high part repeatability, essential for global brands.

To learn why IBM's three-station system enhances consistency:

👉 How IBM Three-Station Machines Work

https://www.victorcn.com/how-three-station-injection-blow-molding-machines-work-process-benefits/

Here is a summary comparing traditional issues and IBM solutions:

| Bottleneck Type | Traditional Issue | IBM Solution |

|---|---|---|

| Multi-part Assembly | Slow, error-prone | Single-piece container |

| Decoration Steps | Extra cost & slow | Molded-in details |

| Consistency | Variations across batches | High repeatability |

| Material Waste | High scrap | Minimal waste |

How Can IBM Streamline Production from Mold to Market for Intricate Packaging?

Complex packaging often involves slow prototyping, mold adjustments, and post-processing.

IBM accelerates this entire workflow through integrated mold → injection → blowing → ejection cycles.

Optimizing the End-to-End Process

1. Mold Design Stage

Modern CAD/CAM ensures accurate molds with fewer revisions.

2. Production Stage

Injection and blowing occur in a synchronized cycle with high stability.

3. Finishing Stage

No trimming or welding—details are formed directly inside the mold.

4. Cost Efficiency

IBM lowers long-term unit cost for medium–high volume runs.

Here is a clear comparison:

| Production Stage | Conventional Method | IBM Approach |

|---|---|---|

| Prototyping | Slow, iterative | Fast, precise |

| Mold Making | Hard to correct | High-accuracy molds |

| Manufacturing | Separate forming processes | Integrated IBM cycle |

| Finishing | Requires cutting | Minimal finishing |

For further reading on packaging sustainability, refer to:

👉 EPA Sustainable Packaging Overview

https://www.epa.gov/smm/sustainable-packaging

Conclusion

Injection blow molding enables complex, efficient, and distinctive packaging.

It solves design and production challenges effectively—helping brands create innovative forms that stand out on the market.

Related Articles

-

Injection Blow Molding vs Extrusion Blow Molding

https://www.victorcn.com/injection-blow-molding-vs-extrusion-blow-molding/ -

How Three-Station Injection Blow Molding Machines Work

https://www.victorcn.com/how-three-station-injection-blow-molding-machines-work-process-benefits/ -

Injection Blow Molding Process Explained

https://www.victorcn.com/products/injection-blow-molding-machine/injection-blow-molding-process/