Introduction: The Monolith is Dead. Long Live the Niche.

For decades, the beauty industry was ruled by economies of scale. Success was measured in millions of identical units rolling off conveyor belts, destined for the shelves of ubiquitous retailers. The packaging playbook was simple: choose a stock bottle, select a stock cap, and stamp your logo. This was the age of the monolith.

That age is over. A seismic shift has occurred, driven by a new generation of consumers who crave authenticity, personalization, and brand stories that resonate with their individual identity. They aren't looking for a mass-market product; they are seeking a beauty ritual, a connection, an experience that feels crafted for them. This has ignited the explosive rise of indie brands, limited-edition collaborations, hyper-personalized skincare, and agile direct-to-consumer (DTC) businesses.

This new landscape presents a fundamental challenge to the old manufacturing model. How do you produce packaging that is as unique, agile, and story-driven as the brand itself, without the million-unit minimums and crippling tooling costs of the past?

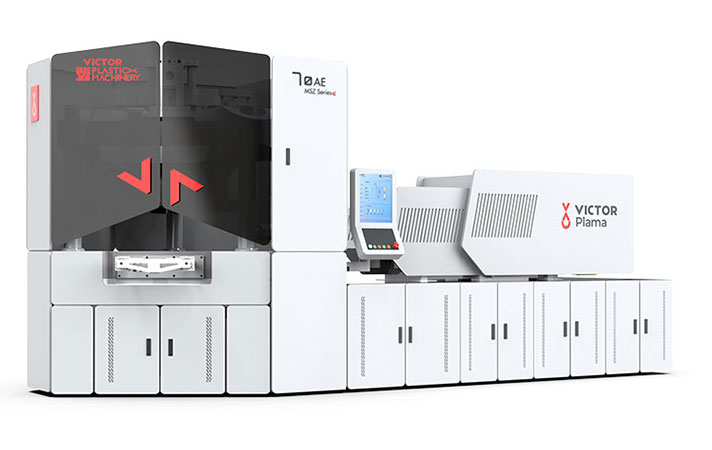

At VICTOR MACHINERY, we saw this revolution coming. We have spent years re-engineering not just our machines, but our entire philosophy, to become the catalyst for this new era. We are the strategic partner for brands who believe that packaging is the most tangible expression of their ethos, and we provide the technology and expertise to make small-batch, customized packaging not just possible, but powerfully profitable.

Part 1: The Drivers of the Customization Revolution

This shift is not a passing trend; it is a permanent restructuring of the market, fueled by powerful forces:

- The Demand for Authenticity: Consumers, especially Millennials and Gen Z, are marketing-averse and story-hungry. They support brands with a clear mission, ethical sourcing, and a founder’s vision. Custom packaging is the physical vessel for that story—its weight, texture, and form communicate values before a single word is read.

- The Power of Agility: Social media trends move at light speed. A brand’s ability to capitalize on a viral moment, launch a seasonal collection, or collaborate with an influencer requires a supply chain that can pivot in weeks, not months. Long lead times and massive minimums are a death sentence for relevance.

- The DTC & E-commerce Imperative: When your package is unboxed in a customer’s home, not picked off a store shelf, it must create a "moment." This unboxing experience is a critical marketing touchpoint, demanding unique, Instagram-worthy packaging that standard stock items cannot provide.

- The Science of Personalization: From skincare formulated based on DNA to foundation mixed to an exact shade, products themselves are becoming bespoke. The packaging must follow suit, feeling personally curated rather than industrially produced.

Part 2: Breaking the Mold: Our Engine for Customization

Traditional injection blow molding was designed for uniformity at massive scale. We have deconstructed and reimagined the process to serve the opposite goal: maximum variability at accessible scale. Here is how we do it:

1. The Modular Mold System: Where Flexibility is Engineered

Our breakthrough innovation is a proprietary modular mold system. Think of it not as a single, fixed, and prohibitively expensive mold, but as a sophisticated Lego set for packaging.

- Interchangeable Cavity Inserts: The core mold frame remains constant. What changes are the precision inserts that define the bottle's shape. Swapping these inserts allows a brand to produce multiple unique designs using the same base machine setup, dramatically reducing the cost and time for each new SKU.

- Neck Finish Library: A wide array of standardized, yet high-end, neck finishes (for screw caps, droppers, pumps) can be paired with various body designs. This allows for mixing and matching to create a signature look without custom tooling for every component.

2. Advanced Decoration & Finishing On-Demand

A custom shape is only the beginning. The surface is the canvas. Our integrated production cell approach brings decoration in-house, eliminating a costly and slow secondary supplier.

- In-Mold Labeling (IML): Seamlessly integrate premium paper or plastic labels during the molding process for a flawless, durable, 360° decorated finish.

- Hybrid Digital Printing: Ideal for ultra-short runs or variable designs such as numbered limited editions, without printing plates.

- Embossing, Debossing & Specialty Finishes: Tactile brand details, matte–gloss contrasts, and subtle pearlescent effects that elevate shelf and hand feel.

3. The "Smart Minimum" Economics

We have abolished the archaic 100,000-unit minimum.

- Feasible Batch Sizes: Economical production from 5,000–10,000 units, ideal for launches, pilots, and limited editions.

- Transparent Costing: Clear, upfront pricing aligned with small-batch growth realities.

Part 3: The VICTOR MACHINERY Collaboration: Your Brand, Amplified

We are not an order-taking factory; we are a collaborative studio for brand expression. Our process is designed to be an extension of your creative team.

Phase 1: The Creative Sprint

We start with your vision, not a catalog. Bring us a mood board, a founder’s story, or a sketch on a napkin. Our design engineers translate your aesthetic into technically feasible, manufacturable designs that retain every ounce of your creative intent.

Phase 2: The Rapid Reality Check

Within days, not weeks, we provide 3D renderings and functional prototypes. You can hold, feel, and test a sample of your custom design, allowing for quick iterations based on ergonomics, dispensing performance, and aesthetic appeal. This fail-fast, refine-quickly approach is the heartbeat of modern brand development.

Phase 3: The Scalable Launch

Once the design is perfected, our modular system allows for a swift transition to production. We manage the entire supply chain for the packaging component, delivering a turnkey solution that is ready for your filling line.

Phase 4: The Growth Partnership

As your brand scales from 10,000 units to 100,000 units, our system scales with you. We can seamlessly increase output and introduce automation, ensuring your signature packaging remains consistent and cost-effective through every stage of your growth journey.

Conclusion: Your Signature, in Plastic and Promise

The future of beauty belongs to the brave, the authentic, and the personalized. It belongs to brands that understand their packaging is not a cost, but a core brand asset—a silent ambassador that speaks of quality, intention, and care.

The old manufacturing gatekeepers, with their inflexible minimums and endless timelines, are relics of a fading era. VICTOR MACHINERY represents the new paradigm: a partner built for speed, flexibility, and creative empowerment.

We provide the tools to build a brand that looks, feels, and operates differently. Because in the age of the niche, the only standard is having none at all.

Ready to build the packaging your brand story deserves?

Contact VICTOR MACHINERY. Let's prototype the future, in small batches and bold ideas.

About VICTOR MACHINERY

VICTOR MACHINERY is the leading partner for agile, customized plastic packaging in the beauty and personal care industry. By fusing decades of precision injection blow molding expertise with a revolutionary modular mold system and "Smart Minimum" production model, we empower indie brands, DTC disruptors, and established giants alike to create signature packaging without signature hurdles. We turn visionary brand stories into tangible, market-ready reality.