Technical Features

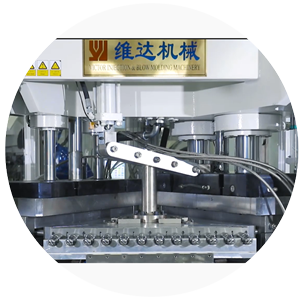

Dual-cylinder clamping system, specially engineered for high precision and stability.

Ensures fast mold opening and closing, shorter idle cycles, and higher overall efficiency.

Dual proportional hydraulic control system provides precise motion control and smooth operation, delivering up to 25% higher energy efficiency compared with conventional vane pump drives.

Horizontal injection design offers reliable plasticizing performance, easy operation, and simplified maintenance. Single crossbeam clamping structure allows for quick mold installation and excellent accessibility, improving productivity and setup convenience.

Ensures fast mold opening and closing, shorter idle cycles, and higher overall efficiency.

Dual proportional hydraulic control system provides precise motion control and smooth operation, delivering up to 25% higher energy efficiency compared with conventional vane pump drives.

Horizontal injection design offers reliable plasticizing performance, easy operation, and simplified maintenance. Single crossbeam clamping structure allows for quick mold installation and excellent accessibility, improving productivity and setup convenience.

Product Application

Advantage

Special designed single crossbar dual-cylinder balance clamping system,for fast opening and closing mold while ensuring uniform distribution.

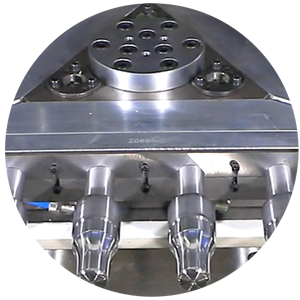

Unique rotating mechanism design, and equipped with automatic lubrication system,ensure rotation precision be consistent.

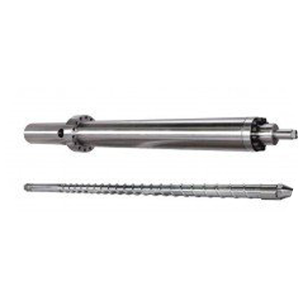

Alternative efficient plasticizing mixing screw, optimization of the injection unt,improve the injection stability and accuracy.

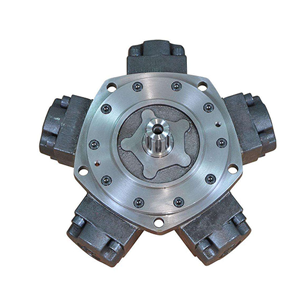

Equipped with electro-hydraulic servo system, the machine is running stable, low noise, high response and energy saving of 25% to 45%.

Screw optimization design, clamp screw head assembly, with good plasticizing ability, wear resistance.

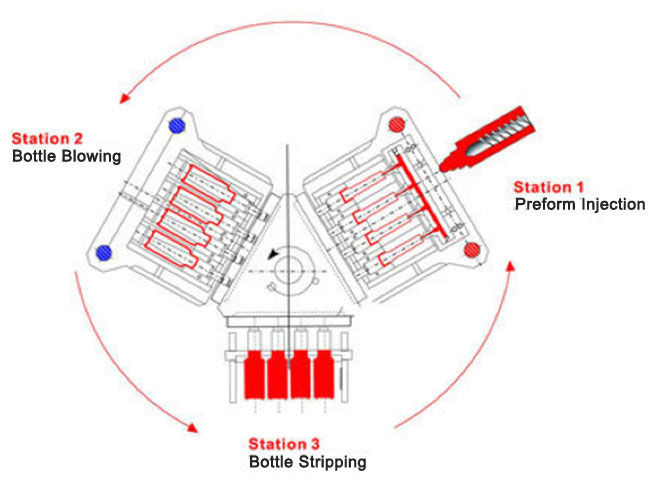

Processing principle

The MSZ60S is a model-specific IBM solution optimized for producing small and medium-volume pharmaceutical, cosmetic and laboratory packaging. Designed with a dual-cylinder clamping structure, stable core-rod rotation and fast, clean-room compatible operation, the MSZ60S delivers consistent dimensional accuracy and reliable long-term performance for HDPE and PP bottles.

Parameter Table

| Injection system | Unit | MSZ60S | |

| Screw Diameter | mm | 50 | 55 |

| Screw L/D | L/D | 23:1 | 23:1 |

| Injection weight(HDPE) | g | 298 | 360 |

| Max.screw speed | rpm | 10-235 | |

| Heating capacity | KW | 10.8 | |

| Clamping system | |||

| Clamping force of injection | KN | 750 | |

| Clamping force of blowing | KN | 89 | |

| Max.Platen size(L*W) | mm | 740×390 | |

| Min.Mold thickness(H) | mm | 280 | |

| Heating capacity of mould | KW | 6 | |

| Stripping system | |||

| Stripping stroke | mm | 200 | |

| Dry cycle | sec | 3.5 | |

| Driving system | |||

| Motor power | KW | 30 | |

| Hydraulic pressure | Mpa | 15 | |

| Product range | |||

| Suitable bottle range | ml | 5-800 | |

| Max.bottle height | mm | ≤200 | |

| Max.Dia.of bottle | mm | ≤100 | |

| Others | |||

| Min.Air pressure | Mpa | 1.0 | |

| Discharge rate of compressed air | M³/min | ≥0.8 | |

| Water flowage | M³/h | 5 | |

| Total rated power with mold heating | KW | 46.8 | |

| Dimension(L*W*H) | M | 4.3×1.69×2.45 | |

| Net weight | ton | 8.6 | |