Why Startups Are Choosing Injection Blow Molding Technology?

In recent years, a noticeable trend has emerged in the manufacturing landscape: an increasing number of startups—across packaging, medical devices, cosmetics, and consumer goods—are prioritizing investments in injection blow molding (IBM) technology.

This shift is driven by technological improvements, market expectations, and the unique operational demands of early-stage companies.

For startups, where efficiency, speed-to-market, and scalability determine survival, IBM has evolved into a strategic tool for growth.

Can Injection Blow Molding Technology Be Used for Startup Product Development?

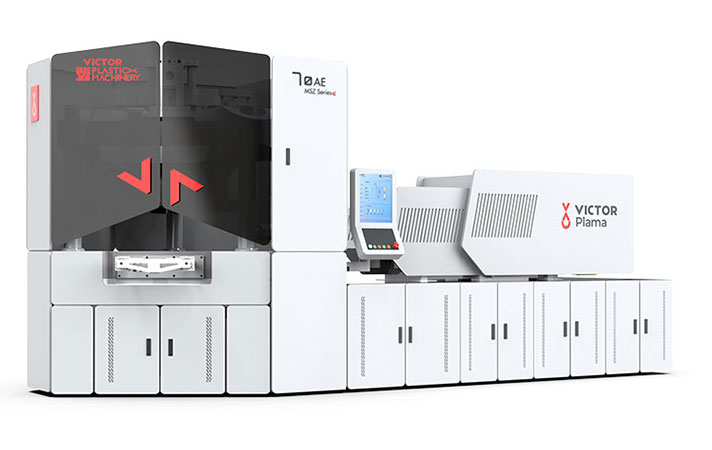

The machine shown above is the MSZ30 Series Injection Blow Molding Machine, one of Victor Machinery’s popular models for producing small plastic bottles and containers.

1. Unmatched Precision and Consistency for High-Quality Outputs

Startups entering premium or regulated markets—such as medical devices, pharmaceutical packaging, or cosmetics—must deliver flawless products from the first batch.

Injection blow molding excels here, offering:

- ultra-precise preform injection

- consistent wall distribution

- no flash, no trimming

- clean-room compatible production

Learn more about how IBM works:

➡️ Injection Blow Molding Process Explained

2. Cost Efficiency That Aligns With Startup Budgets

While IBM equipment often has a higher initial investment than extrusion blow molding, startups benefit from:

- Material Savings (up to 30%)

- Lower labor requirements (high automation)

- Minimal post-processing

- High repeatability and low rejection rate

For more machine details, visit:

➡️ Victor’s IBM Machine Series

3. Versatility to Meet Diverse Market Needs

IBM supports a wide range of thermoplastics—including PP, PE, PET, PETG, PC, COC—making it ideal for startups who need to adapt quickly.

This flexibility allows a single machine to produce:

- pharmaceutical vials

- cosmetic bottles

- food-grade containers

- small household packaging

Fast mold-changing capability also accelerates product iterations.

If you wish to understand bottle structures:

➡️ Types of Bottles for IBM

What Factors Should Startups Consider When Implementing IBM Technology?

Above is an Injection Blow Molding Mold used for precision bottle forming.

Learn more about our molds:

➡️ Injection Blow Molds →

4. Compliance With Strict Industry Regulations

IBM’s closed-mold, contamination-free process is ideal for regulated industries such as:

- pharmaceuticals

- sterile medical packaging

- food-contact packaging

Learn more about Victor Machinery’s background and certifications:

➡️ About Victor Machinery

5. Scalability to Support Rapid Growth

Modern IBM systems are modular and scalable:

- Start with small cavity machines

- Scale to higher-cavity systems

- Integrate with automation over time

This makes IBM ideal for startups that expect rapid growth.

Need help choosing a machine size?

➡️ Contact Victor Engineers

Conclusion

If you’d like to explore more packaging solutions, visit our

➡️ Packaging Solutions Page →

For startups, investing in injection blow molding is not just a manufacturing decision—it is a strategic choice to:

- improve quality

- reduce costs

- stay flexible

- meet regulatory standards

- scale efficiently

IBM empowers startups to differentiate their brand, speed up development, and increase profitability.

🚀 Recommended Resources for Startup Packaging Projects

If you're building a new product line or entering the packaging market, the following beginner-friendly guides will help you:

-

👉 Injection Blow Molding Machines

Explore models ideal for startups—from compact MSZ30 units to large multi-cavity IBM systems. -

👉 Types of Bottles Made by IBM

Learn which designs (5ml–1L) are most suitable for startup use. -

👉 How Three-Station IBM Machines Work

Understand preform injection, blowing, stripping and why they create higher-quality bottles. -

👉 Energy-Saving Innovations in IBM Systems

Reduce energy cost—especially important for startups with limited budgets.