Plastic Bottle Production Equipment

Victor Machinery provides a complete range of equipment for plastic bottle manufacturing, including IBM machines, precision moulds, and auxiliary systems. Our solutions support bottle sizes from 2ml pharmaceutical containers to 2L food and household packaging.

Victor’s IBM Series delivers high-precision bottle molding from 1ml to 2L for pharmaceutical, cosmetic, food, and household packaging. Each model ensures stable wall thickness, excellent neck accuracy, and zero-flash molding.

- ✔ Premium zero-flash molding

- ✔ High neck accuracy & consistent quality

- ✔ Compatible with PE, PP, PETG & more

IBM Machine Series

Explore Victor Machinery’s full range of Injection Blow Molding (IBM) machines for high-precision plastic bottle production, covering models from 1ml pharmaceutical bottles to 2L household containers.

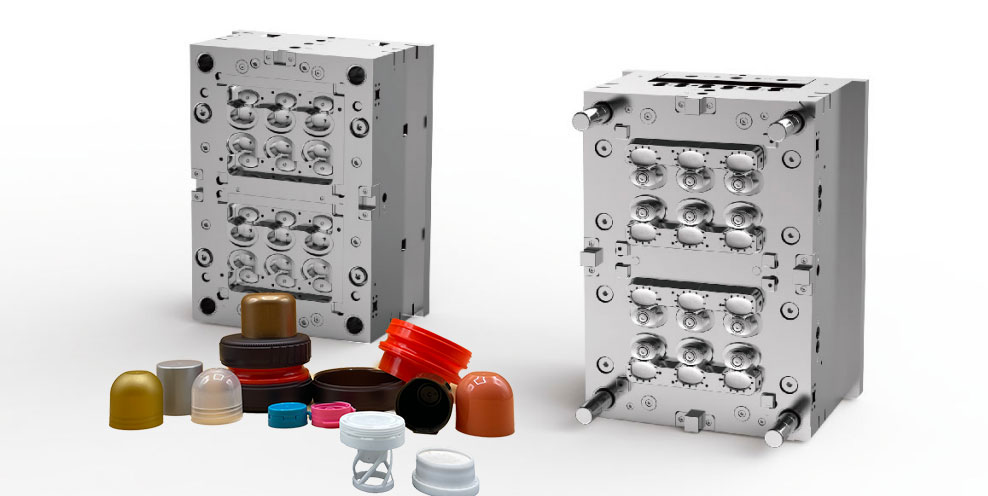

Injection Blow Molding Moulds

(IBM Moulds)

Victor Machinery designs and manufactures high-precision IBM moulds for bottle and cap applications, supporting MSZ series machines as well as Jomar and Uniloy platforms.

I.B.M Bottle Moulds

Our bottle moulds are compatible with MSZ series IBM machines and custom-made for Jomar and Uniloy systems.

They ensure accurate neck finish, stable bottle wall thickness, and long service life with efficient cooling design.

Injection Cap Moulds

We supply multi-cavity injection cap moulds for pharmaceutical, cosmetic, beverage, and household applications.

All moulds are optimized for perfect fitment, high durability, and stable high-speed production.

Automated & Intelligent IBM Production Solutions

Auxiliary

Equipment

Ensures stable mold heating and cooling to maintain consistent bottle quality and accurate wall thickness during IBM production.

Provides efficient cooling for injection blow molding machines, keeping oil and mold temperatures stable for continuous and reliable operation.

Supplies clean and stable compressed air required for molding, stretching, ejecting, and driving pneumatic components in IBM systems.

Performs automated quality inspection to detect bottle defects such as scratches, deformation, contamination, and dimension errors.

Product

Application

Our Partner

Trusted by Global Brands

Trusted by global brands in pharmaceutical, cosmetic, personal care and household packaging industries. Our injection blow molding technology ensures stable quality and long-term reliability.

Looking for high-precision injection blow molding equipment? 👉

Visit our dedicated IBM Machine Series pageFrequently Asked Questions

Ready to Start Your IBM Project?

Get expert engineering support and customized injection blow molding (IBM) solutions designed for pharmaceutical, cosmetic, household and food packaging applications.

Contact Us →